BRAKE CLEANER SPRAY

3 FUNCTIONS

Degreaser Dust Remover Particle Remover

Rapid evaporation rate + maximum efficiency

Guaranteed free of acetone,

chlorinated solvents and aromatics

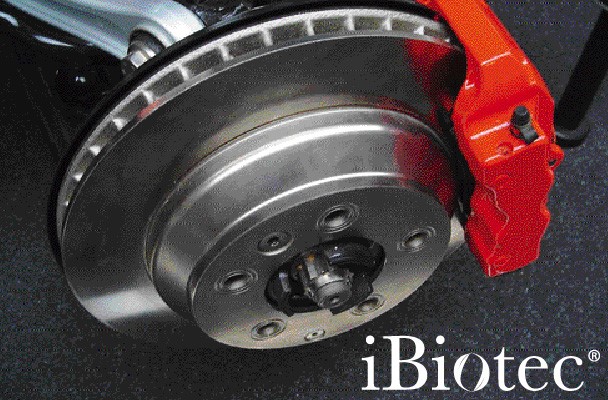

BIOSANE NF 100 is a mixture of high-index KB solvents, used to clean and maintain all brake system components. Platelets, cylinder disks, caliper segments, drums.

It is compatible and effective on all types of brakes, including cast iron, composite, ceramic and carbon/carbon

Fatty residues

They come mainly from brake fluids, cardanic greases, cylinders and pistons, accidental oil leaks from the vehicle itself or the roadway.

Dusts

Mainly from the roadway or chassis, climatic pollution, sludge or traffic.

Particles

These are the famous PF 10s; they come from brake pad wear, but also from tyre wear and road surfaces.

BIOSANE NF 100's rapid evaporation and its very high solvent power mean it has many other uses:

- Carburettor and clutch cleaning

- Oil filter degreasing, cleaning diesel injectors, flow meters and rims.

- Degreasing assemblies with complex shapes

- Degumming slides of machine tools and press tool ball columns

- Cleaning plastics, technical parts, PVC joinery, etc.

BIOSANE NF 100 is compatible with all metals, thermosets or thermoplastics except polystyrene.

It has no effect on paints, elastomers (hoses) or plastics. Unlike many brake cleaning products on the market, BIOSANE NF 100 is guaranteed free of acetone, chlorinated solvents and aromatics (xylene, toluene), which, in addition to their toxicity, strongly attack these materials.

The ISO EN 982 standard deals specifically with safety in the field of hydraulics. It was strengthened by the French decree 2008-1156 of 07 November 2008 that enforced the prevention of all risks, in this area in particular. Biosane NF 100 is used as a hose cleaning agent that allows any oil leaks or ruptures to be detected.

HOW TO USE AND RECOMMENDATIONS

Shake the container well before use. Spray 10 to 15 cm away from the surfaces to be cleaned. Disassemble brake pads before cleaning them.

TYPICAL PHYSICAL AND CHEMICAL SPECIFICATIONS

|

SPECIFICATIONS |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Fluid |

- |

|

Colour |

Visual |

Colourless |

- |

|

Odour |

Olfaction |

Odourless |

- |

|

Density at 25° C |

NF EN ISO 12185 |

683 |

kg/m3 |

|

Refractive index |

ISO 5661 |

1.4120 |

- |

|

Freezing point |

ISO 3016 |

-50 |

°C |

|

Solubility in water |

- |

0 |

% |

|

Kinematic viscocity at 40°C |

NF EN 3104 |

0.52 |

mm²/s |

|

Water content |

NF ISO 6296 |

<0.005 |

% |

|

Residue after evaporation |

NF T 30-084 |

0 |

% |

|

Vapour pressure at 20°C |

NF EN 13016-1 |

113 |

hPa |

|

PERFORMANCE SPECIFICATIONS |

|||

|

SPECIFICATIONS |

STANDARDS |

VALUES |

UNITS |

|

KB index |

ASTM D 1133 |

134 |

- |

|

Evaporation rate |

- |

<1 |

mn |

|

Surface tension at 20° C |

ISO 6295 |

18.7 |

N/m |

|

Copper blade corrosion 100h at 40° C |

ISO 2160 |

1a |

Rating |

|

FIRE SAFETY SPECIFICATIONS |

|||

|

SPECIFICATIONS |

STANDARDS |

VALUES |

UNITS |

|

Flash point (closed cup) |

ISO 2719 |

<23 |

°C |

|

Flash point |

ASTM E 659 |

<230 |

°C |

|

Lower explosion limit |

NF EN 1839 |

0.9 |

% (density) |

|

Upper explosion limit |

NF EN 1839 |

9.5 |

% (density) |

|

TOXICOLOGICAL SPECIFICATIONS |

|||

|

SPECIFICATIONS |

STANDARDS |

VALUES |

UNITS |

|

CMR, irritating and corrosive substance content |

CLP Regulation |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

% |

|

Emissions of hazardous compounds, CMR, irritants and corrosive substances at 160° C. |

GC-MS |

0 |

% |

|

ENVIRONMENTAL SPECIFICATIONS |

|||

|

SPECIFICATIONS |

STANDARDS |

VALUES |

UNITS |

|

OVC Content (Organo-Volatile Compounds) |

- |

100 |

% |

|

Sulphur content |

GC-MS |

0 |

% |

|

Benzene content |

ASTM D6229 |

0 |

% |

|

Total halogen content |

GC-MS |

0 |

% |

|

Chlorinated solvents content |

- |

0 |

|

|

Aromatic solvents content (Toluene, Xylene, etc.) |

- |

0 |

- |

|

Ketone content (acetone, methyl ethyl ketone, etc.) |

- |

0 |

- |

|

Content of compounds with a GWP (global warming potential) |

- |

0 |

% |

|

Content of compounds with ODP (ozone layer destruction potential) |

- |

0 |

% |

PRESENTATION

|

|

SPRAY CAN 650 ml Net volume 500 ml .jpg) |

Looking for another product?

|

Discover our entire range by clicking on the photo |

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.

.jpg)